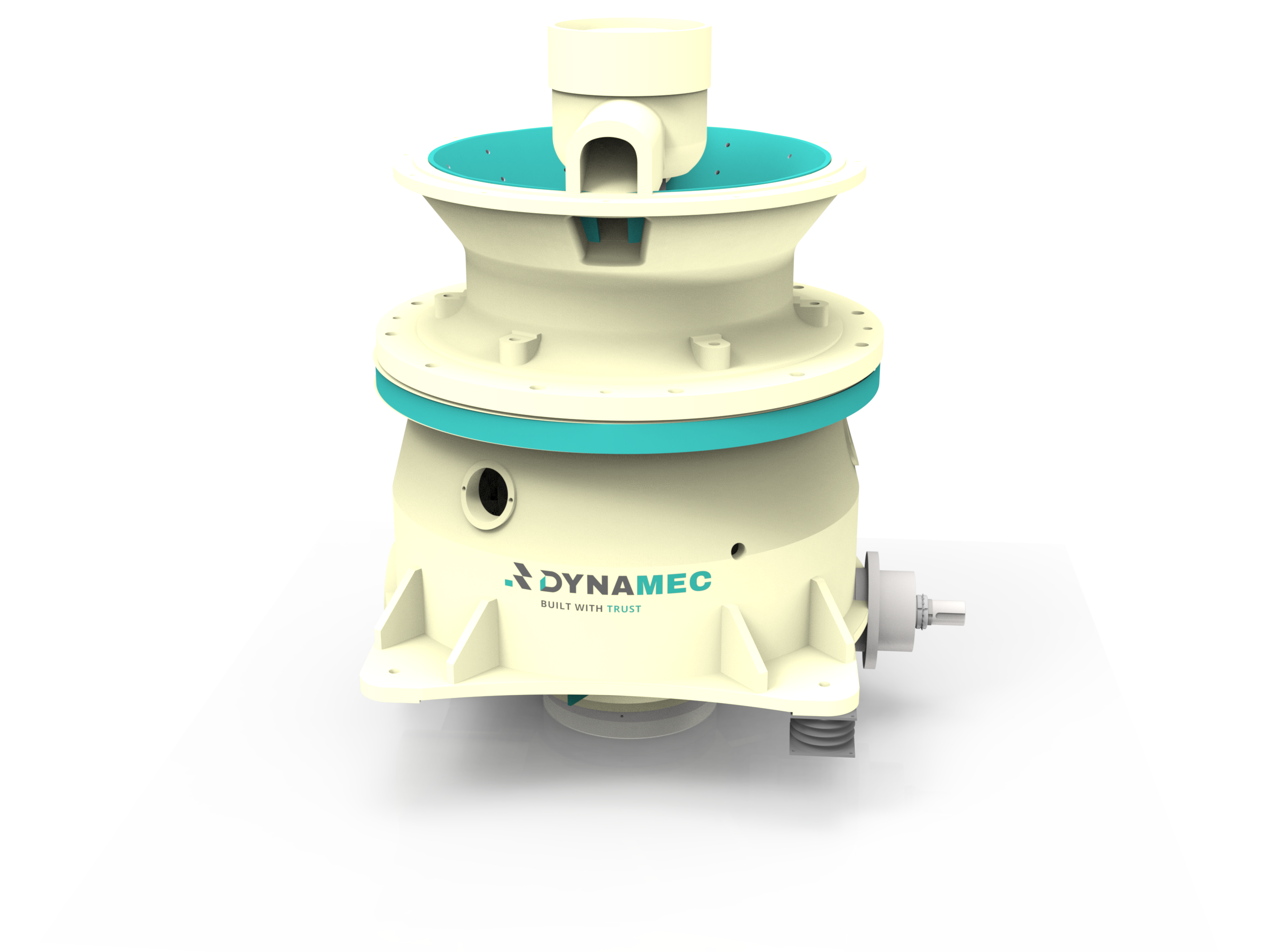

Cone Crusher

Dynamec Cone Crushers are built for secondary and tertiary crushing applications, delivering consistent performance with superior product shape and high reduction ratios. Designed with advanced hydraulic and automation systems, these crushers ensure precise control, reduced downtime, and lower operating costs.

Download BrochureOverview

A cone crusher works by compressing the feed material between a moving cone (mantle) and a fixed outer concave liner. As the material enters the crushing chamber, it is squeezed and reduced in size as it moves downward through the chamber. The adjustable CSS (Closed Side Setting) provides flexibility to achieve the desired output size.

Distinct Advantages

- High reduction ratio with excellent cubic product shape

- Hydraulic setting adjustment and overload protection

- Heavy-duty design with robust frame and high-strength components

- Efficient tramp release system for safety and reduced downtime

- Optional automation and remote monitoring features

- Low operating and maintenance costs

Typical Applications

Cone crushers are widely used for secondary, tertiary, and quaternary crushing stages in aggregates production, mining operations, and recycling applications. Ideal for processing hard and abrasive materials such as granite, basalt, iron ore, and river gravel.

Image for illustration only – actual design may vary.

Image for illustration only – actual design may vary.

Technical Data Sheet — Representative Models

| Model | Feed Opening (mm) | Recommended Feed Size (mm) | Output Size (mm) | Capacity (tph) | Motor Power (kw) | CSS Range (mm) | Mantle Dia (mm) |

|---|---|---|---|---|---|---|---|

| AEI-CC150 | 190 | 150 | 28 – 45 | 120 – 160 | 110 | 16 – 38 | 950 |

| AEI-CC200 | 250 | 180 | 19 – 65 | 160 – 220 | 160 | 18 – 40 | 1150 |

| AEI-CC250 | 325 | 250 | 22 – 75 | 180 – 270 | 187 | 25 – 55 | 1200 |

Design Highlights

- Heavy-duty mainframe and advanced bearing system

- Optimized speed and throw for superior performance

- Replaceable wear liners and easy access to components

- Energy-efficient drive with smooth operation

Operation & Maintenance

- Monitor CSS and adjust regularly for consistent output.

- Inspect liners and replace when worn beyond tolerance.

- Ensure proper lubrication of bearings and gears.

- Check hydraulic system and tramp release regularly.

- Follow all safety protocols before performing maintenance.