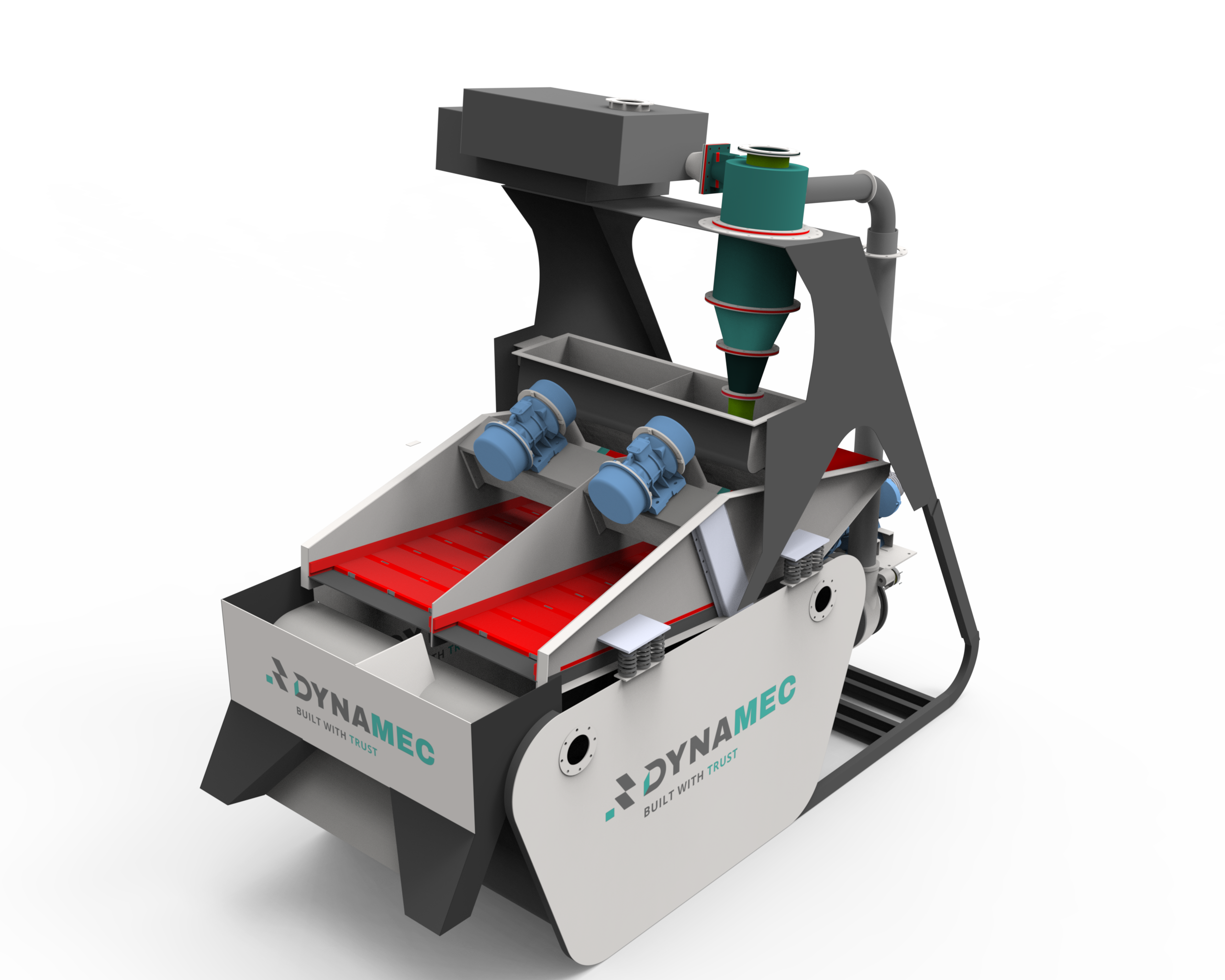

Sand Washer (Hydrocyclone)

Dynamec Hydrocyclone Sand Washers are designed to remove impurities, silt, and ultra-fines from sand, ensuring superior quality washed material suitable for concrete and construction applications. Engineered with advanced hydrocyclone technology, these systems maximize water recovery and minimize energy consumption.

Download BrochureOverview

The Hydrocyclone-based sand washer works by feeding slurry into the hydrocyclone where centrifugal forces separate water and fines. The underflow produces clean sand with controlled moisture, while the overflow carries fines and dirty water to a recovery system. This method ensures precise separation, efficient washing, and minimal environmental impact.

Distinct Advantages

- High efficiency removal of silt, clay, and ultra-fines

- Low power consumption with high water recovery

- Compact design with minimal footprint

- Replaceable wear parts for long service life

- Customizable capacities for different plant sizes

- Environment-friendly operation with reduced water wastage

Typical Applications

Hydrocyclone sand washers are widely used in manufactured sand (M-Sand) plants, quarry dust washing, construction sand preparation, and mineral washing plants. Ideal for ensuring high-quality fine aggregates for concrete and asphalt mixes.

Image for illustration only – actual design may vary.

Image for illustration only – actual design may vary.

Technical Data Sheet — Representative Models

| Model | Capacity (tph) | Hydrocyclone Dia (mm) | Pump Power (kW) | Water Requirement (m³/hr) | Product Moisture (%) | Weight (kg) |

|---|---|---|---|---|---|---|

| AEI-HC100 | 30 – 45 | 300 | 15 | 80 – 100 | 12 – 15 | 4,500 |

| AEI-HC150 | 45 – 60 | 400 | 22 | 120 – 150 | 10 – 12 | 6,800 |

| AEI-HC250 | 120 – 180 | 400 – 600 | 30 | 150 – 200 | 8 – 10 | 9,200 |

Design Highlights

- Robust hydrocyclone with anti-abrasive lining

- Heavy-duty slurry pump for continuous operation

- Compact steel frame skid-mounted design

- Easy integration with existing washing plants

Operation & Maintenance

- Ensure consistent slurry feed for optimal performance.

- Regularly check pump and hydrocyclone wear parts.

- Maintain proper lubrication of rotating components.

- Monitor water flow and adjust to control product quality.

- Follow all safety and lock-out procedures during servicing.