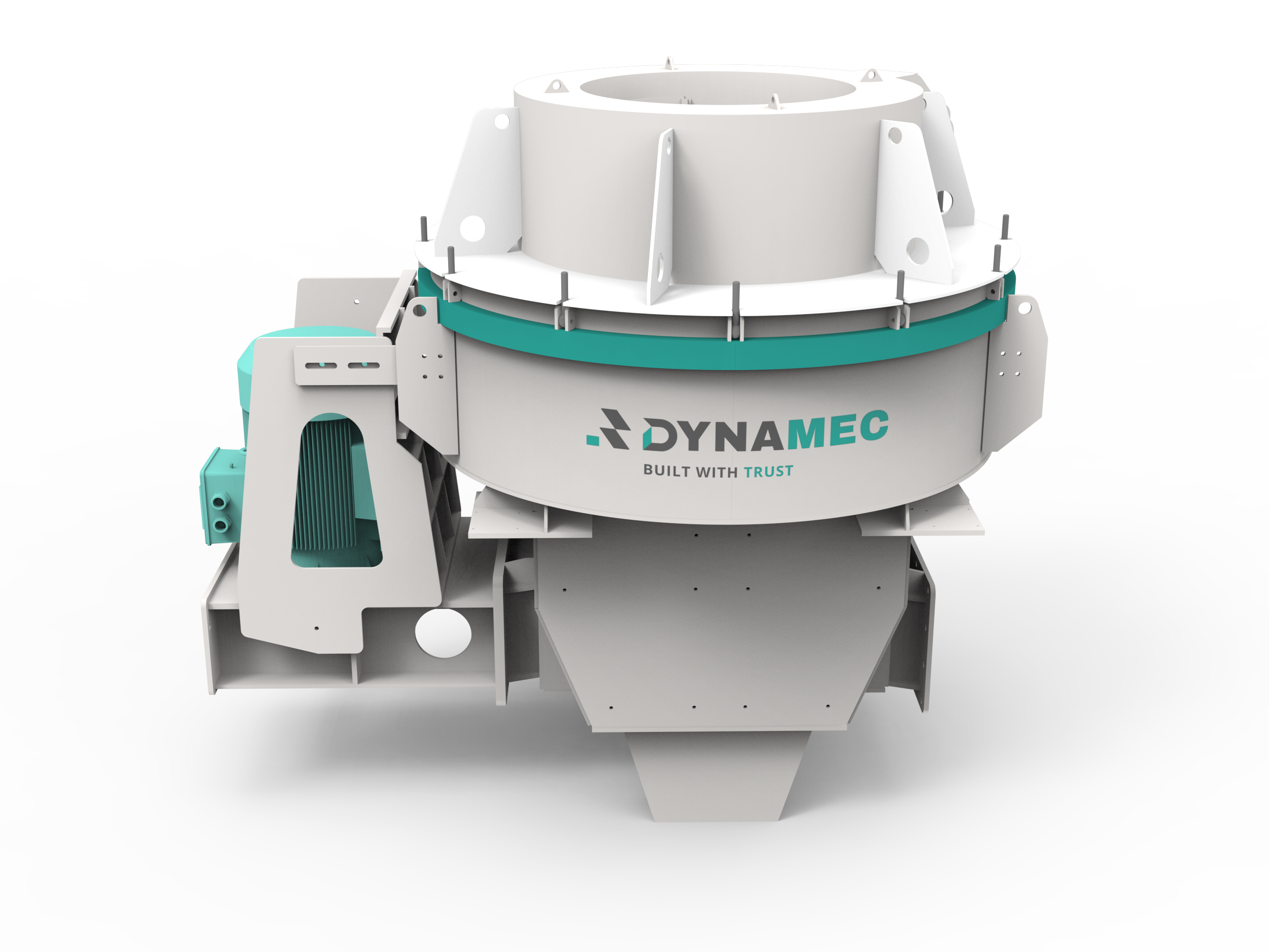

VSI Crusher

Dynamec VSI (Vertical Shaft Impact) Crushers are designed for producing high-quality cubical aggregates and manufactured sand. Using rock-on-rock or rock-on-metal crushing principles, VSI crushers deliver consistent particle shape, excellent fines control, and energy efficiency.

Download BrochureOverview

A VSI crusher accelerates material by centrifugal force against a wear-resistant anvil or rock shelf. The impact breaks down the feed into precisely shaped particles. This technology is ideal for producing manufactured sand (M-Sand) and fine aggregates with superior surface texture.

Distinct Advantages

- Produces cubical aggregates with excellent particle shape

- High sand production efficiency with low operating costs

- Rock-on-rock principle minimizes wear parts consumption

- Flexible rotor configurations for different applications

- Hydraulic opening system for quick inspection and maintenance

- Optional air classification for ultra-fine products

Typical Applications

VSI crushers are widely used in the production of manufactured sand, road base materials and in mining operations for fine crushing. Ideal for granite, basalt, quartz, and other hard and abrasive materials.

Image for illustration only – actual design may vary.

Image for illustration only – actual design may vary.

Technical Data Sheet — Representative Models

| Model | Body Dia (mm) | Max Feed Size (mm) | Rotor Diameter (mm) | Capacity (tph) | Motor Power (kw) | Product Size (mm) |

|---|---|---|---|---|---|---|

| AEI-VSI100 | 1800 | 25 | 750 | 30 – 70 | 110 | 0 – 14 |

| AEI-VSI150 | 2100 | 35 | 850 | 50 – 120 | 132 – 160 | 0 – 20 |

| AEI-VSI200 | 2200 | 40 | 900 | 70 – 140 | 160 – 187 | 0 – 20 |

| AEI-VSI250 | 2250 | 40 | 950 | 70 – 160 | 187 – 220 | 0 – 22 |

| AEI-VSI300 | 2400 | 40 | 1000 | 90 – 220 | 220 – 250 | 0 – 25 |

Design Highlights

- Heavy-duty rotor with balanced design for smooth operation

- Replaceable anvil and wear parts for extended service life

- Adjustable rotor speed for product flexibility

- Compact structure with easy access for maintenance

Operation & Maintenance

- Ensure feed is clean and properly graded.

- Monitor rotor speed for consistent product size.

- Regularly check wear parts and replace when needed.

- Maintain lubrication of bearings and rotor system.

- Follow safety protocols before servicing.