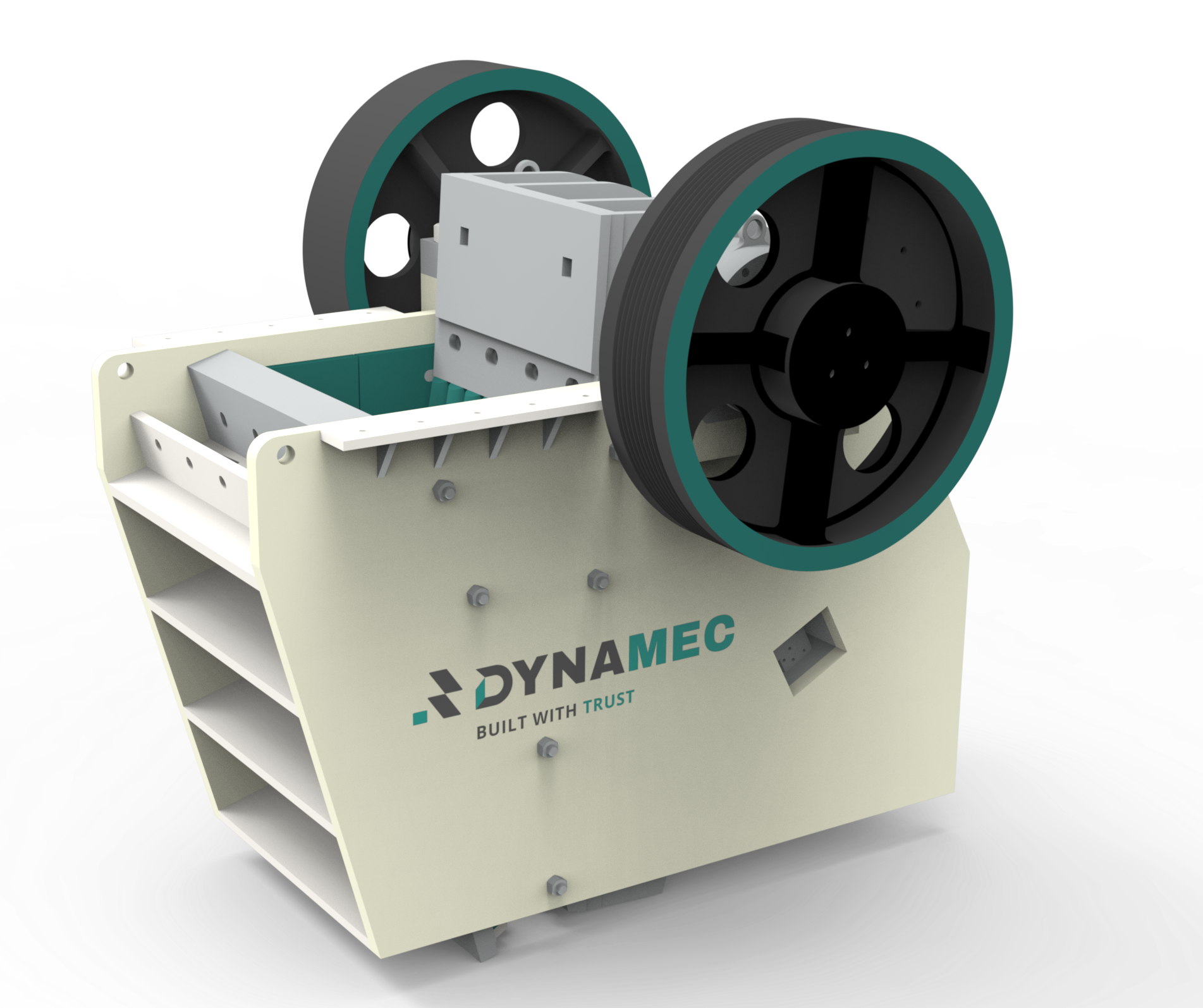

Jaw Crusher

Dynamec Jaw Crushers are engineered as heavy-duty primary crushers capable of handling the toughest materials with exceptional reliability. Designed for continuous operation, these machines deliver high reduction ratios and uniform product size, making them the backbone of crushing circuits worldwide.

Download BrochureOverview

A jaw crusher works by compressing material between a stationary jaw plate and a moving jaw plate. The material enters the crushing chamber from the top and is gradually reduced in size until it exits at the bottom. Adjustable closed-side settings (CSS) allow operators to fine-tune output size, while heavy-duty bearings and a robust frame ensure long service life even under severe operating conditions.

Distinct Advantages

- High crushing ratio up to 6:1 with uniform output shape

- Deep, symmetrical crushing chamber for consistent feed flow

- Replaceable high-manganese jaw plates for extended wear life

- Heavy-duty spherical roller bearings reduce downtime

- Hydraulic or mechanical CSS adjustment for quick setting changes

- Optional flywheel guards, dust suppression and automatic lubrication system

Typical Applications

Ideal for primary crushing of hard and abrasive materials including granite, basalt, river gravel, iron ore, quartzite, limestone, slag, and recycled construction debris. Commonly used in mining, quarrying, aggregate production, concrete recycling, and industrial mineral processing.

Image for illustration only – actual design may vary.

Image for illustration only – actual design may vary.

Technical Data Sheet — Representative Models

| Models | Feed Opening (mm) | Max Feed Size (mm) | Output Size (mm) | Capacity (tph) | Motor Power (kW) | CSS Range (mm) | Crusher Speed (RPM) |

|---|---|---|---|---|---|---|---|

| AEI-150 | 900 × 600 | 550 | 80 – 150 | 100 – 150 | 90 | 80-110 | 250-275 |

| AEI-250 | 1100 × 800 | 750 | 100– 260 | 170 – 250 | 110 – 132 | 90 – 175 | 250-275 |

| AEI-300 | 1200 × 900 | 850 | 130 – 350 | 300 – 400 | 160 – 187 | 110 – 250 | 250-275 |

Design Highlights

- Welded, stress-relieved steel frame for strength and durability

- High inertia flywheels for smooth crushing and energy efficiency

- Replaceable cheek plates and toggle seats for easy maintenance

- Optional hydraulic toggle for quick clearing of tramp iron

Operation & Maintenance

- Ensure even feed distribution and avoid overloading.

- Regularly check jaw plate wear and rotate or replace when needed.

- Maintain proper lubrication of bearings and toggle seats.

- Inspect drive belts and adjust tension to prevent slippage.

- Follow safety lock-out procedures before servicing.